Mastering Your Ride: The Ultimate Fuel Pressure Sensor Guide

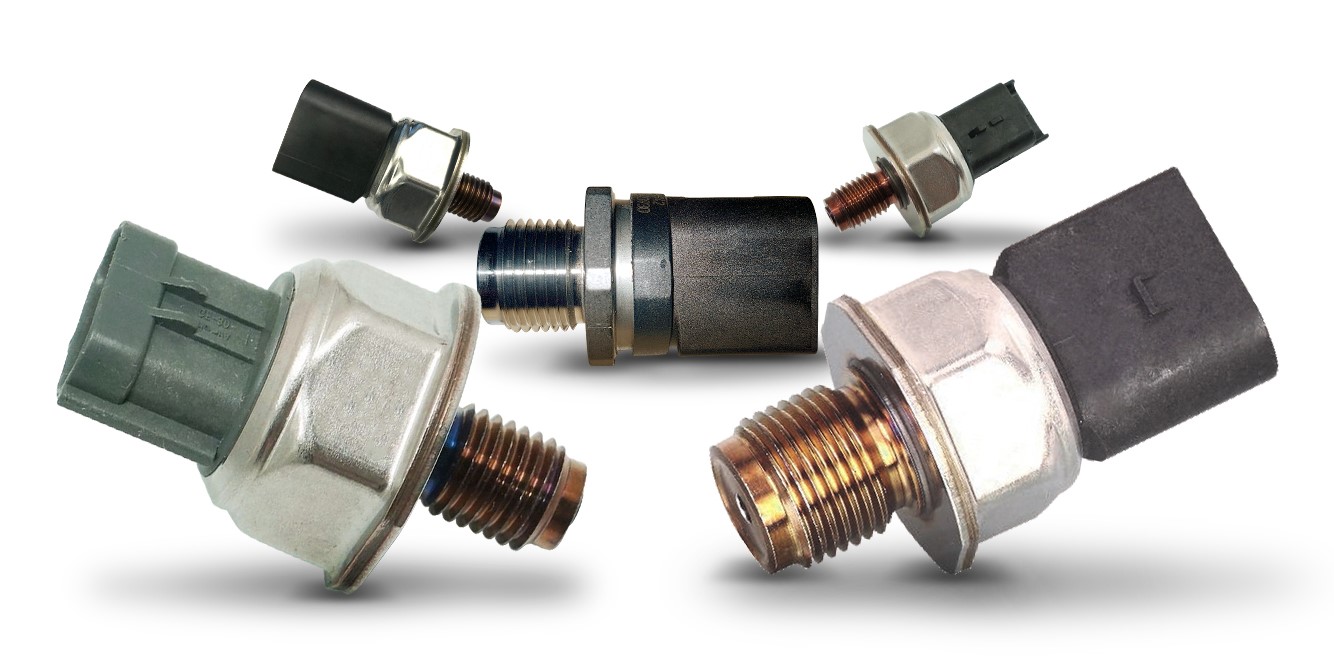

When it comes to ensuring your vehicle runs smoothly and efficiently, understanding the importance of the fuel pressure sensor is crucial. This small yet vital component plays a key role in monitoring and regulating the fuel pressure within your engine’s fuel system. A properly functioning fuel pressure sensor contributes to optimal engine performance, fuel efficiency, and emissions control.

In this guide, we will delve deep into the intricacies of the fuel pressure sensor , exploring its functions, types, common issues, and maintenance tips. Whether you are a seasoned mechanic or a car enthusiast looking to broaden your knowledge, mastering the details of this essential sensor can significantly enhance your ride and ensure that your vehicle operates at its best. Join us as we unlock the secrets of the fuel pressure sensor and empower you with the information you need to take charge of your vehicle's performance.

Understanding Fuel Pressure Sensors

Fuel pressure sensors play a crucial role in the functioning of modern fuel injection systems. They are responsible for monitoring the pressure of fuel within the system and ensuring that the engine receives the correct amount of fuel for optimal performance. When the fuel pressure is too high or too low, it can lead to poor engine performance, increased emissions, and potential engine damage. Understanding how these sensors work is essential for maintaining your vehicle's health.

These sensors operate by generating a voltage signal that corresponds to the fuel pressure they detect. When the pressure changes, the sensor transmits this information to the vehicle's engine control unit, which adjusts the fuel delivery accordingly. This ensures that the engine runs efficiently across various conditions, such as acceleration, deceleration, and idling. The technology behind fuel pressure sensors has evolved, offering greater precision and reliability compared to older mechanical systems.

Regular maintenance and timely replacement of faulty fuel pressure sensors can prevent costly repairs down the line. Symptoms of a failing sensor may include erratic engine behavior, difficulty starting, or changes in fuel efficiency. Vehicle owners should be proactive in monitoring sensor performance and consider consulting a professional mechanic if they suspect issues with their fuel pressure sensor. Proper understanding and attention to this component can contribute significantly to the overall performance and longevity of your vehicle.

Installation and Calibration

Installing a fuel pressure sensor requires careful attention to detail to ensure accurate readings and reliable performance. Start by identifying the recommended location for installation, which is usually on the fuel rail or close to the fuel line. Make sure to gather necessary tools such as wrenches, pliers, and a clean rag to manage fuel spills. Before starting the installation, it's crucial to relieve the fuel system pressure to avoid any dangerous sprays of fuel. This can typically be done by removing the fuse for the fuel pump and running the engine until it stalls.

Once you have access to the installation point, remove any existing sensors or fittings as required. Clean the mounting surface thoroughly to prevent debris from contaminating the fuel system. When installing the new fuel pressure sensor, apply a small amount of thread sealant to the threads of the sensor to ensure a secure, leak-free fit. Tighten it to the manufacturer's specifications to avoid damage while ensuring it is snug enough to prevent leaks.

After installation, calibration is an essential step to guarantee the sensor operates correctly. Connect the sensor to the vehicle's ECU and power up the ignition without starting the engine. Use a diagnostic tool to read the fuel pressure values and compare them with the manufacturer's specified range. If adjustments are necessary, follow the calibration procedure found in the sensor's manual. Proper installation and calibration will help maintain optimal engine performance and fuel efficiency, giving you peace of mind on the road.

Troubleshooting Common Issues

When a fuel pressure sensor malfunctions, it can lead to a range of issues affecting vehicle performance. One common problem is inaccurate readings, which can result in poor engine performance or fuel efficiency. If you notice fluctuations in your fuel gauge or your vehicle struggles to start, it’s wise to check the sensor and its connections. Corroded connectors or damaged wiring can also contribute to faulty readings, so ensuring everything is clean and secure is essential.

Another issue that frequently arises is a complete failure of the fuel pressure sensor. This often manifests as a check engine light activation or error codes specific to the fuel system. In such cases, diagnosing the exact cause is crucial. Using an OBD-II scanner can reveal specific trouble codes associated with the fuel system, helping you pinpoint whether the sensor needs replacement or if the problem lies elsewhere in the system, such as with the fuel pump or the fuel injectors.

Finally, it’s important to address the symptoms of a fuel pressure sensor problem before they escalate. If you experience stalling, hesitation during acceleration, or unexpected engine shutdowns, these could indicate that the sensor is not functioning correctly. Regular maintenance checks of the fuel system, including the sensor, can prevent these issues from worsening and ensure that your vehicle runs smoothly and efficiently.